Inventory Verification in Manufacturing Companies

Inventory verification in manufacturing is a critical control process used to physically verify raw material (RM), work-in-progress (WIP), and finished goods (FG) and reconcile them with ERP or stock records.

Manufacturing companies deal with large SKU volumes, multiple storage locations, continuous production, and frequent material movement. Because of this, differences between physical stock and book records are common.

Physical inventory verification in manufacturing ensures:

- Accurate stock records

- Proper valuation of RM, WIP, and FG

- Audit readiness

- Strong internal controls

This article explains how inventory verification is practically carried out in manufacturing companies, step by step, with controls to prevent duplication, omission, and manipulation.

Why Inventory Verification Is Important in Manufacturing Companies

In a manufacturing environment, inventory is spread across:

- Raw material stores and yards

- Production floors and WIP locations

- Finished goods warehouses and dispatch areas

Without regular physical verification, companies may face:

- Incorrect inventory balances

- Overstatement or understatement of stock

- Inaccurate WIP reporting

- Obsolete or slow-moving inventory remaining unidentified

- Audit qualifications and control weaknesses

Physical inventory verification helps management ensure accuracy of records, better controls and reliable financial reporting.

Physical Verification of Raw Material (RM)

Raw materials may include bulk materials, components, chemicals or consumables stored in bins, racks or open yards.

Physical verification of raw material generally includes:

- SKU-wise and location-wise counting

- Verification of material description and identification

- Identification of slow-moving, non-moving or obsolete raw material

- Reconciliation of physical quantity with ERP or stock registers

Accurate RM verification helps prevent production disruptions and working capital blockage.

Physical Verification of Work-in-Progress (WIP)

WIP inventory is inherently complex as it exists at various stages of production.

Physical verification of WIP involves:

- Identification of different production stages

- Verification of semi-finished goods lying on shop floors

- Validation of quantities at each process stage

- Coordination with production and operations teams

- Reconciliation with WIP and production records

Proper WIP verification ensures correct cost allocation, valuation and reporting.

To understand our audit-ready approach, explore our

Inventory Verification Services for Manufacturing Companies

Physical Verification of Finished Goods (FG)

Finished goods are typically stored in warehouses, godowns or dispatch areas and may be packed or unpacked.

Physical verification of finished goods includes:

- SKU-wise verification of finished products

- Verification of packed, unpacked and ready-to-dispatch goods

- Identification of damaged, rejected or obsolete finished goods

- Verification of goods lying with third-party warehouses, if any

FG verification improves order fulfilment accuracy and inventory visibility.

Inventory Verification Methodology in Manufacturing Companies

A structured inventory verification methodology generally includes:

- Planning and understanding inventory locations

- Mapping of storage areas and SKU categories

- Physical counting on a SKU-wise and location-wise basis

- Cut-off procedures as on the verification date

- Identification of damaged, obsolete or non-usable inventory

- Reconciliation with ERP or inventory records

- Preparation of variance and observation reports

Technology tools such as mobile applications, barcode or QR-based systems can significantly improve speed, accuracy and traceability during verification.

Importance of Tagging, Location Control and Movement Restriction During Inventory Verification

In large manufacturing facilities, the risk of duplicate counting or missing inventory is very high, especially when the same SKU is stored across multiple locations. Such risks may arise due to operational movement, poor location control, or intentional and unintentional manipulation.

To mitigate this risk, proper tagging and location control are critical:

- Where one SKU is stored at multiple locations, either the inventory batches or the storage locations must be clearly identified or tagged before commencing physical verification.

- Where one SKU is stored at a single fixed location, tagging of individual goods may not be necessary. In such cases, location tagging alone is sufficient to ensure accurate counting.

It is also essential that inventory movement is restricted during the verification process. Goods should not be moved between locations until physical verification and reconciliation with inventory records are fully completed. Movement during verification increases the risk of duplication, omission and unreliable reconciliation.

These controls ensure that inventory is verified once and only once, thereby improving accuracy, reliability and audit confidence.

Common Challenges in Manufacturing Inventory Verification

Manufacturing companies often face challenges such as:

- Large SKU volumes

- Multiple storage and production locations

- Continuous production during verification

- Incomplete or outdated records

- Movement of inventory during physical counting

These challenges can be addressed through proper planning, trained manpower, location control and technology-enabled verification.

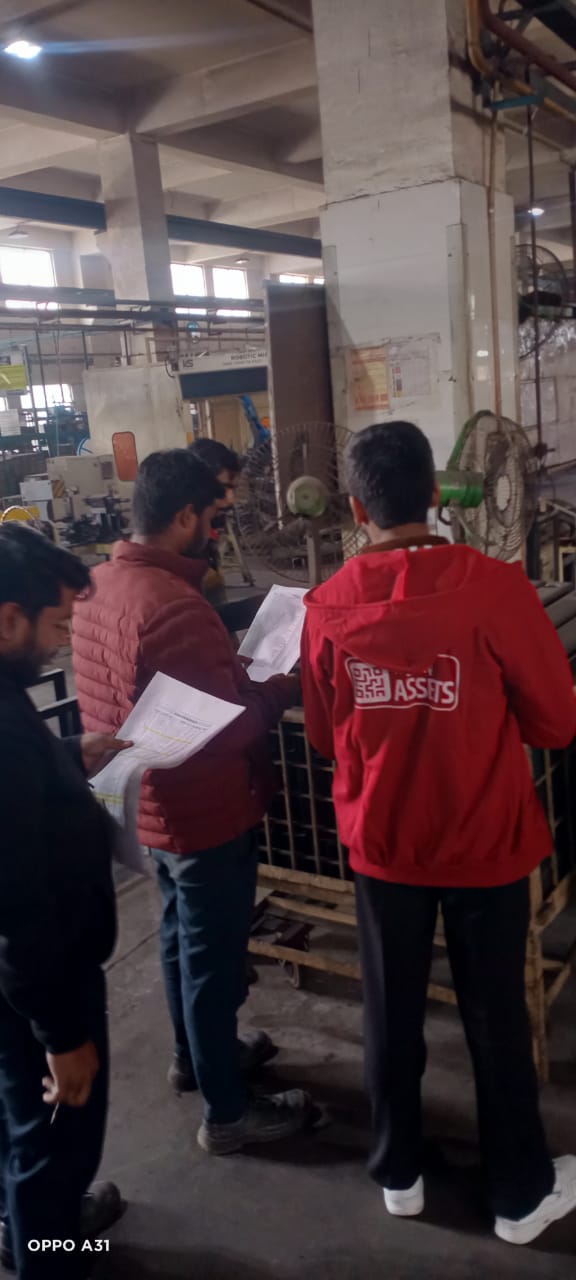

Professional Inventory Verification Services

Due to the complexity involved, many manufacturing companies engage independent professionals for inventory verification services. Professional verification ensures objectivity, accuracy and audit-friendly documentation.

👉 For Inventory Verification Services covering Raw Material (RM), Work-in-Progress (WIP) and Finished Goods (FG), please visit our

Inventory Verification Services page.

🔗 https://tagmyassets.com/inventory-verification-services/

Conclusion

Physical inventory verification of RM, WIP and FG is essential for manufacturing companies to maintain accurate records, strengthen internal controls and support audits. A structured methodology combined with proper tagging, location control and movement restriction ensures reliable and meaningful verification results.