Inventory verification for retail chains is a critical process to ensure accurate stock records, prevent losses, and maintain audit-ready inventory across multiple locations. This inventory verification for retail chains ensures better control, faster counting, and zero duplication or missed stock entries. This guide explains inventory verification for retail chains in a simple step-by-step manner.

That’s why organizations conduct inventory physical verification to match actual stock with book/ERP records and ensure accuracy. Inventory verification for retail chains helps prevent stock mismatch, pilferage, and wrong replenishment decisions.

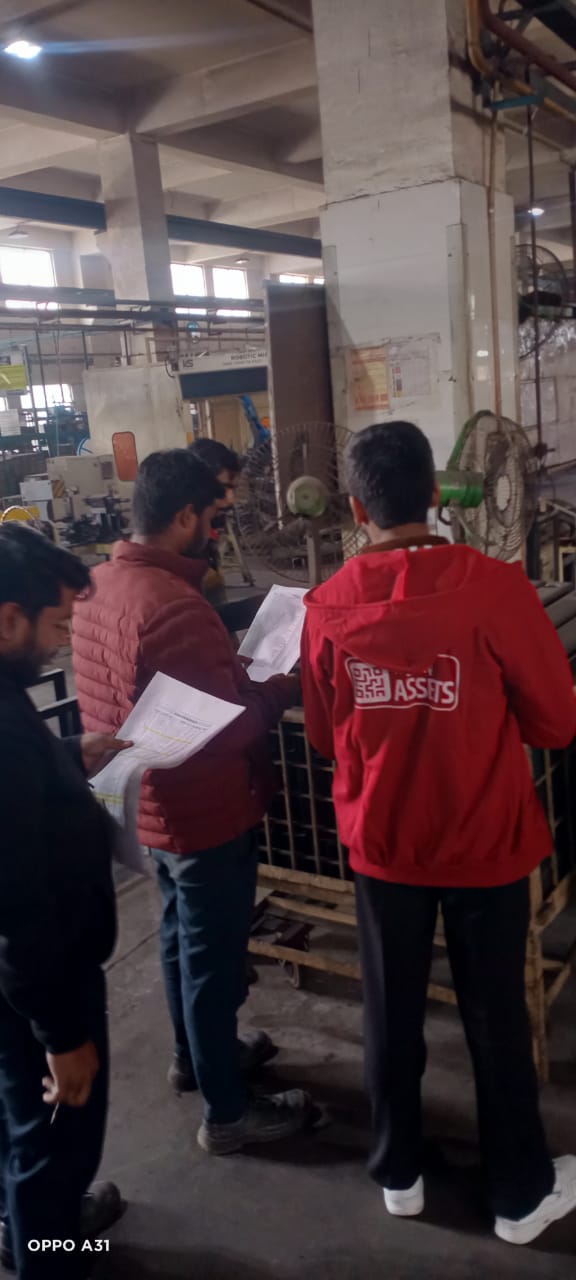

At TagMyAssets, we follow a structured and technology-driven approach for inventory verification using barcode/QR scanning tools and mobile-based data capturing, ensuring high accuracy and audit-ready reporting.

To understand our end-to-end audit-ready approach, also explore our

Inventory Verification Servicesfor warehouses, retail chains, and manufacturing organizations.

✅ Inventory Verification for Retail Chains: Meaning and Importance

Inventory verification is the process of physically checking stock quantities and conditions and reconciling the same with inventory records, ERP systems, or stock registers.

The objective is to identify:

- Shortages or excess stock

- Damaged, obsolete, expired or slow-moving items

- Wrong placement or wrong SKU issues

- Mismatch between physical stock and book records

This process helps management and auditors gain confidence that inventory balances reported in financial statements are reliable.With our inventory verification for retail chains, brands get clean stock data, faster audits, and better store-level control.

✅ Why Inventory Verification Is Important

Without proper inventory verification, organizations may face:

- Wrong stock valuation in books

- Pilferage / loss not identified

- Wrong planning for purchase and production

- Overstocking or understocking

- Internal control gaps and audit observations

- Incorrect financial reporting and decision-making

A well-planned verification ensures clean data, better control, and improved operational efficiency.Inventory verification services help retail chains maintain accurate stock records and reduce losses.

✅ Inventory Verification Methodology for Retail Chains (Step-by-Step)

Step 1: Planning & Preparation

Before physical counting starts, our team performs a structured pre-verification planning, which includes:

✅ Understanding your stock nature (RM / FG / WIP / trading / retail items)

✅ Identifying storage areas (warehouse, shop floor, racks, bins, yards, stores)

✅ Finalizing verification date & cut-off timing

✅ Defining scope (SKU-wise / bin-wise / location-wise)

✅ Ensuring the latest stock report / ERP extract is available

✅ Allocating teams location-wise for smooth execution

This ensures the verification is systematic, fast, and error-free, especially in large sites with multiple locations.

Step 2: Location Tagging & Rack Number Mapping

To ensure full control and traceability, we first start with location tagging and storage mapping.

✅ Every floor/store/warehouse zone is marked properly

✅ Each Rack / Bin / Shelf / Aisle reference is captured

✅ Rack number entry is done in the system

This helps in:

- Easy tracking of stock location

- Better accountability for each storage area

- Future audits and verification speed

- Stronger inventory controls

Step 3: SKU-wise Scanning, Counting & Punching in System

After mapping, we start physical verification through SKU-wise scanning and counting.

✅ Items are scanned using barcode/QR-based tools

✅ Quantity is counted and punched directly in the system

✅ Real-time data capture ensures accuracy

We follow a controlled scanning method because in warehouses and retail environments:

- If everything is scanned without control, chances of double scanning increase

- If scanning is missed, items can remain uncounted

- High-volume counting can create confusion without structured rules

So our process ensures minimum duplication, minimum missed entries, and maximum accuracy.

Step 4: Stock Condition Check & Observations

Along with counting, we also check the physical condition of inventory, such as:

- Damaged or broken items

- Expired inventory (where applicable)

- Slow-moving / non-moving stock

- Wrongly placed items

- Unidentified stock without proper label/SKU

These observations are captured for management control and reporting.

Step 5: Cut-Off Check (To Ensure Correct Stock as on Date)

Inventory numbers can change due to inward/outward movement.

That’s why we follow cut-off checks such as:

✅ Ensuring no dispatch happens during verification

✅ Marking inward/outward movement separately

✅ Verifying GRN / issue records near cut-off time

✅ Ensuring physical stock matches “as on date” records

This makes the results more reliable and audit-friendly.

Step 6: Reconciliation With ERP / Stock Register

After counting, we match physical quantities with book/ERP stock.

We prepare variance reports such as:

- Excess stock (physical > book)

- Shortage stock (physical < book)

- Mismatch due to wrong SKU / wrong location

- Condition-based variances (damaged/obsolete)

This reconciliation helps the organization identify the root cause and take corrective action.

Step 7: Final Reporting & Deliverables

After verification and reconciliation, TagMyAssets submits structured reports such as:

✅ Location-wise summary

✅ SKU-wise count report

✅ Variance quantity & value report

✅ Slow-moving / non-moving analysis (if required)

✅ Damaged/expired/obsolete stock list

✅ Management-friendly reporting & audit-ready documentation

Our reports are suitable for:

- Statutory audits

- Internal audits

- Management review

- ERP cleanup and control strengthening

✅ Technology & Tools We Use

To improve accuracy, transparency and speed, we use:

- Mobile-based verification tools

- Barcode / QR-based scanning

- SKU-wise structured count sheets

- Location mapping & rack tagging

- Downloadable data reports anytime

✅ Data can be downloaded from the app multiple times, which helps in:

- preparing different report formats

- cross-checking and reviewing

- reconciliation and audit documentation

✅ Industries We Serve

Our inventory verification services are widely used in:

- Retail stores and multi-location retail chains

- Warehouses and distribution centers

- Manufacturing plants (RM/WIP/FG)

- FMCG and consumer goods businesses

- Trading & distribution companies

- Logistics and service organizations

✅ Why Choose TagMyAssets for Inventory Verification?

TagMyAssets provides structured inventory verification across India with technology-enabled execution.

We ensure:

✅ High accuracy and speed

✅ Organized location-wise control

✅ Strong reconciliation and clean reporting

✅ Audit-ready documentation

✅ Professional ground teams for multi-location projects

FAQs

1) Do you verify inventory across multiple locations?

Yes, we execute inventory verification across multiple sites including warehouses, branches, retail outlets and plants.

2) Can you verify inventory even if ERP stock is not clean?

Yes. We first conduct clean physical verification and then assist in reconciliation and stock record cleanup.

3) Do you provide variance report with value impact?

Yes, we provide variance reports both in quantity and value, depending on the client’s requirement and data availability.

4) Can you support barcode/QR-based inventory counting?

Yes. We use barcode/QR-based tools and mobile systems to improve speed and accuracy.

✅ Also explore our Inventory Verification Services:

Inventory Verification Services https://tagmyassets.com/inventory-verification-services/

📩 For enquiry: connect@tagmyassets.com

Reference: ICAI (Institute of Chartered Accountants of India) – https://www.icai.org/